Air valve performance investigation

THE CHALLENGE

Our client needed to ensure the correct operation of a rising main which had three air valves fitted. We were asked to implement live monitoring equipment on the three air valves along the rising main, to investigate the performance of these air valves. Ensuring air valves are operational can reduce the likelihood of pipeline structural failures due to surge developing from the interaction of entrapped air with the flowing sewage column.

ACTION

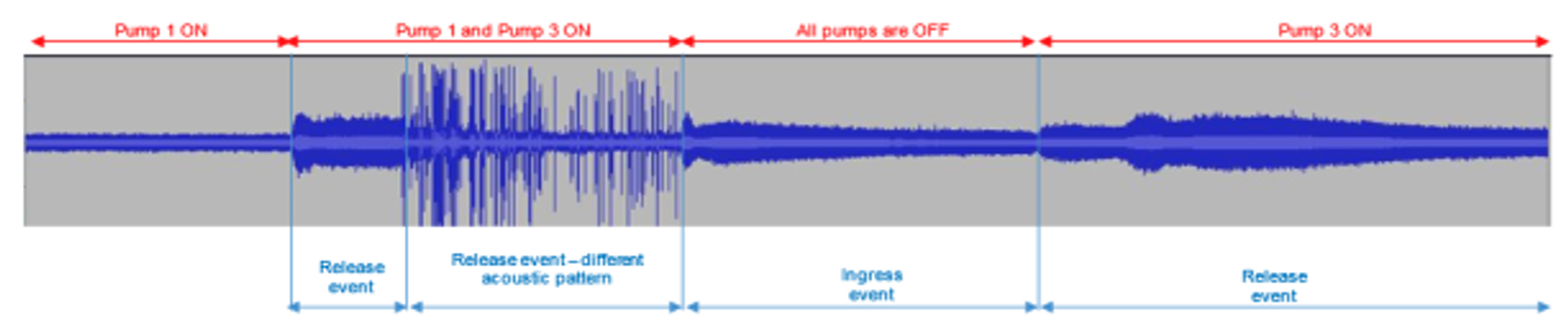

We visually assessed each air valve allowing the make, model and construction material to be determined. We then fitted our patented SSiren air valve monitor onto the three air valves along the rising main. These monitors were left to record air valve operation over a one week period, where noise patterns of the air passing through the air valve could be monitored and recorded. We were also supplied with the pumping data from the client’s SCADA system, detailing the rising mains flow over the course of the monitoring period.

RESULTS

Our assessment concluded that air valve 1 did not operate due to incorrect positioning along the main, air valve 2 was found to be operable but leaking throughout the monitoring period and air valve 3 was found to vent at regular intervals suggesting this valve could be the most critical air valve along the pipeline.

The air valve operations correlated with the pump operations. Different acoustic patterns corresponding to different functions of the combination air valve (kinetic and automatic functions) were obtained. This work allowed our client to remediate the leaking air valve and create a focused maintenance programme on the identified critical air valve to reduce the likelihood of pipeline structural failure.