THE PIPELINE ASSET HEALTH

& PERFORMANCE SPECIALIST

Supporting the water and gas sectors

About Advanced Engineering Solutions

We are specialist water and gas pipeline and pipeline equipment engineers with core expertise in mechanical, material, electronics and software engineering. We provide high quality engineering services to pipeline operators and suppliers.

Solving Your

common CHALLENGES

Asset health & performance

Integrity Assessments

Statutory Gas Inspections

Pipeline Management

Our Services

SmartCAT – Industry leading inspection tooL

SmartCAT, our patented water pipeline condition assessment technology, enables rapid non-intrusive assessment of the condition of metallic pipes.

latest from OUR knowledge centre

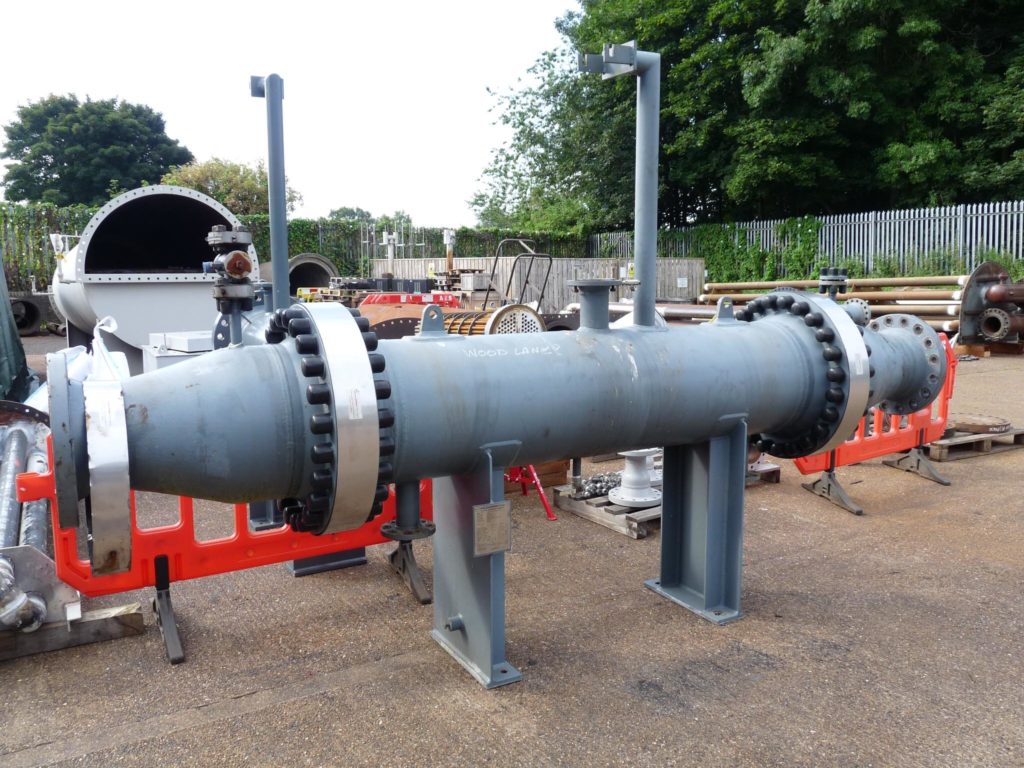

Heat exchanger revalidation for utilities client

Advanced Engineering Solutions (AES) was contracted by a client in the utilities sector to carry out the revalidation of a heat exchanger.

SmartCAT® inspections in France

In autumn 2024, Advanced Engineering Solutions (AES) was contracted by Suez to complete a series of non-destructive condition assessments on a ductile iron pipe in Brittany, North West, France.

Advanced Engineering Solutions (AES) appoints new Managing Director

Infrastructure Asset Health Business owned by South Staffordshire Plc appoints Andrew Lobley as it accelerates growth and diversification plans.

HEAT EXCHANGER REVALIDATION (PSSR)

With heat exchangers categorised as pressure vessels under the Pressure Systems Safety Regulations 2000 (PSSR), their integrity must be inspected on a regular basis.